SDGs Interviews: Talking Zero Hunger with Yuji Murata

SARAYA is one of Japan’s leading companies that implement the United Nations Sustainable Development Goals (SDGs). This is the seventh chapter of SARAYA’s SDGs interview series telling the story of those behind SARAYA and how they are working to achieve these goals. In this edition, we spotlight Dr. Yuji Murata, a doctor of applied life sciences who is Director of the Natural Materials Laboratory and Production Division, discussing the making of Lakanto, SARAYA’s groundbreaking innovation of zero-calorie sweetener made of all-natural ingredients, and SDG number 2: Zero Hunger.

|

|

How did you come to work at SARAYA?

"We need someone like you!" said Dr. Kunio Shimomura, the general manager of SARAYA Osaka factory. I was visiting their factory to check their R&D (Research and Development) facility. With my master’s degree in microanalytical chemistry almost finished, I already had secured a job at one of the major cosmetics companies, but I thought it wouldn’t hurt to take a look at another company nearby.

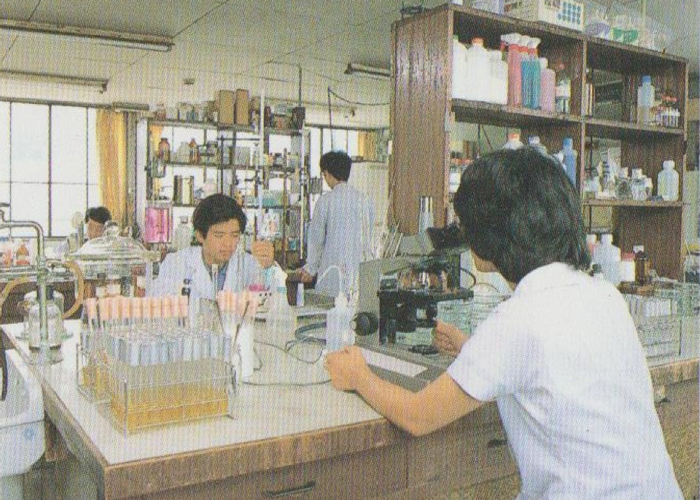

I visited SARAYA after finding a job advertisement at school. When I visited, the laboratory was not only four employees in a prefabricated building with a floor that shook when you walked on it, but it was dirty and had even cockroaches. I thought it was out of the question for me to work there.

After a tour of the factory and the laboratory, I was invited to talk to Dr. Shimomura, the head of the factory, and other employees at the lab, which took up more than 2 hours of conversation. He was so full of passion that made me change my mind, ending up joining this company with a family-like atmosphere in 1983. Sometimes meeting just one person changes your life and that was what happened to me.

In the beginning, They only had basic laboratory devices, but over the years they acquired all the latest devices I wished to have. There, many innovative products were born including Lakanto, the zero-calorie natural sweetener I have been working on. The R&D department now has more than 60 laboratory researchers.

|

| Osaka laboratory. Photo taken years after Dr. Murata joining SARAYA. |

There's nothing more exciting than creating new products that have never existed in the world. Life has been good to me due to being able to achieve the many things I wanted to do in my life at SARAYA.

Could you tell us about your background?

I was born as the youngest of 3 siblings to a farmer family in Sakai City in Osaka Prefecture. Today, the city is well developed, but when I was growing up, it was a rural farming country. My parents were rice farmers, which didn’t have any modern farming machines, but a cow that helped us plow the rice fields. My job after school was to take care of the cow with my older brother through elementary school, feeding it, and handling manure. Other than those chores, I played with friends outside.

Maybe I was interested in growing monk fruits (Luo Han Guo) because of my early farming experience...

Later, I got my Ph.D. at Osaka Prefectural University in applied life science while working at SARAYA. The company helped me to obtain a Ph.D. degree.

Could you tell us about your current job at SARAYA?

Currently, I have a position as Director and General Manager of the Natural Materials Laboratory, Production Division. Until 2014, I had a position in the Product Development Division's Bio-Chemical Laboratory.

I work mainly on two projects. Firstly, I deal with a lot of things related to monk fruit - Lakanto (a zero-calorie sweetener made of natural ingredients) and secondly with natural surfactants, which means detergents made of natural ingredients.

In terms of Lakanto-related works, we do basic research on monk fruit like taste improvement, functional research, productivity improvement of monk fruit cultivation technology, and zero-emissions which includes effective use of monk fruit extraction residue. We also deal with the global development of the Lakanto brand, patent applications and registrations for monk fruit extracts in various countries.

|

| Dr. Murata during a factory presentation. On the left, Mr. Saraya, president of SARAYA. |

Concerning the natural surfactant related work, we are establishing a manufacturing process for soapberry extracts, which is a natural surfactant, and business development.

How did you come to be involved in the development of Lakanto, the world's first plant-derived zero-calorie sweetener at SARAYA?

SARAYA started as a company that manufactures and sells soaps and detergents. With a philosophy in "prevention" which has been in place since 1952, their first product was a medicated liquid hand soap to prevent infectious diseases. Lakanto, our zero-calorie sweetener, was developed with the same concept of ‘preventing’ illnesses.

It was the late Shota Saraya, founder, former president, and father of current President Yusuke Saraya, who proposed the development of a zero-calorie sweetener to replace sugar in order to "prevent" lifestyle-related diseases, especially diabetes and obesity, he himself being a diabetic. At that time, there was no concept of a zero-calorie sweetener but shortly after, through joint research among the Japanese industry, government, and academia, they succeeded in developing the technology for the fermentation and production of ‘erythritol’, a natural zero-calorie sweetener made from glucose. This led us to launch research and development of the world's first zero-calorie sweetener using erythritol.

However, erythritol's sweetness is only 70% that of sugar, which means that it’s not sweet enough, therefore required to be combined with some kind of high-sweetness sweetener. As SARAYA is a nature-oriented company, we researched plant-based sweeteners. We knew stevia and licorice extracts were sweet, but they had some funny aftertaste, so we started to look for new sweeteners in many thesis and research documents. One day I came across a document by a professor in Japan about monk fruit (Luo Han Guo), which is said to grow wild only in the region of Guilin, China.

Initially used for preventing and treating all kinds of illnesses, the monk fruit was called the "Fruit of Longevity" in the region. Local and monks living there have been consuming monk fruit as a raw material of Chinese herbal medicine for cough suppressants over hundreds of years. This long history of eating monk fruit is proof of its safety.

After long research and countless experiments, we managed to combine erythritol and monk fruit extract, creating the world's first plant-derived zero-calorie sweetener, Lakanto, in 1995. The name "Lakanto" is the combination of two Japanese words, “Lakanka”, the name of the monk fruit in Japanese, and "to" in Japanese, meaning "sugar".

|

| Original packaging of Lakanto. |

What was fun and what difficult about developing Lakanto?

When we started, little was known about the monk fruit. We didn’t have any knowledge about cultivation techniques, sweetness quality nor other botanical research results. Hence, all the work we did was always a first in the world. It was quite exciting to do something that nobody else had done before.

When I told Mr. Shota Saraya about the monk fruit, he got so excited that told me to get my passport ready right away. Soon after, Mr. Saraya, the founder, Mr. Yusuke Saraya, his son and current president, myself, and our Lakanto development team visited Guilin, China, starting basic research on the cultivation of the fruit. We did the fruit’s sweetness research and extraction technique development, setting standards, safety research, and performance research in collaboration with local universities and research institutes.

It was 1995 when we started selling Lakanto (crude and unrefined) and after a Memorandum of Understanding (MOU) signing ceremony for the Monk Fruit Sweetener Development Project in June 1998, a joint business agreement with the Chinese Guilin government was created, improving Lakanto even further thanks to the production of high-purity glycosides (refined), naming the new extract Lakanto S, standing for super, special and for Mr. Shota Saraya’s initials.

|

|

| Signing of the Monk Fruit Sweetener Development Project in 1998. | |

The challenge was that we had to do everything on our own as everything was, as mentioned before, new, with no scientists to consult, nor decent academic papers to research. But after all the hard work, we were able to develop the world's first zero-calorie natural sweetener, “Lakanto” in 1995.

Thereafter, we had another kind of hardship. Since SARAYA was a company of detergents and soaps, never dealing with food until then, it was extremely hard to motivate our salespeople. Imagine, no one ever heard about monk fruit, and the price of Lakanto then was more than 10 times higher than sugar. It was a seriously tough job to explain the value of a product at the time when people still did not talk about zero-calorie or sugar-free products.

I accompanied the sales team to drugstores, medical clinics and high-end restaurants across the country to explain Lakanto. I can't even begin to describe how hard it was to coordinate with other departments to come this far. With all their hard work, it gradually gained recognition.

What is Lakanto Development and SARAYA in relation to SDG2, Zero Hunger?

Today China has become an economic powerhouse, but in the 1990s, the living conditions of the people of Guilin were hard, especially for the farmers engaged in agriculture, harsher than you could ever imagine. There was no electricity, no gas nor running water, and the roads were muddy.

Nowadays it is possible to grow monk fruit on the lowlands, but at that time it was difficult just to get to the farms, that had to grow on the steep mountain slopes about a two to three-hour drive from Guilin. It was routine for all of us to get out of the trucks and having to push them as we drove along the mountain roads to get there. Also, the trucks wouldn't go into the cultivation area, so we had to climb for the last 30-40 minutes to finally get to the site. When we got there, it felt like we had conquered the mountain.

Seeing this difficult situation, Mr. Shota Saraya, our founder said, "Monk fruit is a sustainable plant grown in Guilin. A foreign company must not come and monopolize this plant. Why don't we first focus on improving the lives of the farmers and revitalizing Guilin before we make profits for our company?”. President Saraya has been working on the SDGs goals like SDGs 2 Zero Hunger since before the concept of SDGs ever existed. Over the years, with our production multiplied, so did the monk fruit cultivations. The lives of local farmers improved significantly.

In 2015, we built a new factory, Guilin SARAYA Biotech Co., Ltd in Guilin, China, the hometown of monk fruit, capable of manufacturing monk fruit extract and "Lakanto" made from it, in order to provide customers the world safest, most reliable and tastiest sweeteners through thorough traceability and integrated production, from the cultivation of the monk fruit to the manufacturing of the final product of the Lakanto. By the way, monk fruit plants are prohibited to be taken out of the country, so all process to make the extract is done locally.

|

| Photo of the monk fruit fields of SARAYA up in the mountains of Guiling. |

We have signed contracts with selected farmers in Guilin to provide thorough traceability in the entire process of cultivating the monk fruit, i.e., breeding, cultivation techniques, harvest time, and management of pesticides and fungicides. Some may even wonder why we spend so much time and effort in the process of sorting the fruits at the time of arrival to the extraction plant, and even just before extraction, sorting out the moldy and damaged fruits. As a pioneer in the field of monk fruit, SARAYA's commitment is uncompromising and thorough.

In addition, the Guilin Plant has introduced new technologies in almost all of its manufacturing processes to improve the taste and quality of monk fruit extracts. We have applied for an international patent for innovative technology for the refining process that enables us to remove pesticides and odd flavor components, which are not available in other companies. Thus, we continuously focus on improving the quality and taste and aim to develop the world's safest, most reliable, delicious sweeteners. Of course, we hire many local Guiliners employees at SARAYA Biotech Co., Ltd.

Could you explain more about Lakanto as a brand?

Initially, Lakanto was a domestic brand in Japan, but now it has become a global brand, attracting attention not only in Japan but also in the United States, Canada and many other countries. Currently, Lakanto is actually more popular in North America, where awareness of healthy eating habits is high with interest growing in natural, organic, sugar-free, gluten-free, vegan, low sugar, and low-calorie solutions.

Lakanto S Granules are made with calorie-free erythritol as the main ingredient and monk fruit extract blended with it. By combining these ingredients appropriately, it is possible to develop a wide range of Lakanto products. The most popular product of Lakanto is Lakanto S Granules, but we also market “Lakanto Liquid”, “Lakanto White”, “Lakanto Low Carb Sweetener”, and “Lakanto Powdered Sweetener”, depending on how you use it.

|

| Lakanto S, the main product of the Lakanto family. |

On the other hand, we have various derivative products of the Lakanto brand like Lakanto Jam, Lakanto Zero Calorie Candy, Lakanto Chocolate, and Lakanto Plum Wine, etc. Basically, the Lakanto brand is a brand that meets the concept of its main ingredients: natural, sugar-free, low sugar, and low calorie.

These products are popular among diabetics, obese people, and those who are on a diet, especially those who are concerned about their blood sugar level after a meal.

What is your future plan with Lakanto?

As for the future of Lakanto, we aim to develop a Lakanto brand that can be labeled with functionality (e.g., reduction of triglycerides and visceral fat, suppression of postprandial blood glucose increase, etc.) in addition to just the natural and zero-calorie concepts.

The reduction of triglycerides and cholesterol and the suppression of postprandial blood sugar elevation contribute greatly to the damage of vascular endothelial cells and lead to the prevention of lifestyle-related diseases, which have become a social problem worldwide in recent years. We would like to achieve the development of the next generation of Lakanto that helps people all over the world to manage their health.

Could you give us some words for the next generation?

The important things for a product developer are to establish basic research to clarify the evidence, to improve the formulation of value-added products, to register patents if necessary, to publish the results at an academic conference, and to prepare easy-to-understand materials for the sales department. However, these tasks are only part of their duties. Developer/researcher needs to provide a product or service to the world, to help people (customers), and to receive feedback. Then, you could be called a full-fledged researcher or developer.

To achieve this, you need to be able to think on your own and create something new that has never existed before, instead of just doing what you are told to do. You will face many doubts and hardships, but you need to overcome them through work hard and perseverance. Believe in yourself and never give up, no matter what. Be open-minded to understand failures and any harsh comments your boss may say, as even that is an important part of your experience. In the end, the important thing for a member of society is that you find joy in your daily work.