SDGs Interviews: Talking Innovation with Ryota Kihara

SARAYA is one of Japan’s leading companies that implement the United Nations Sustainable Development Goals (SDGs). This is the ninth chapter of SARAYA’s SDG interview series telling the story of those behind SARAYA and how they are working to achieve these goals. In this edition, we spotlight Ryota Kihara, Manager at the Product Development Department, and discuss the development of the cold chain infrastructure with SARAYA’s innovative Rapid Freezer and the SDG number 9: Industry, Innovation, and Infrastructure.

|

|

How did you come to join SARAYA?

I was studying plasma sterilization at the Faculty of Engineering of the University of the Ryukyus, a national university in Okinawa, Japan, for my master’s degree, when I met Mr. Tomomasa Itarashiki, SARAYA’s current general manager of the Product Development Department. He had joined our laboratory as a researcher, and getting to know him working together on research and looking up to him as this cool person, made me interested in the company that sent him to my faculty, especially because they had an advanced research facility on plasma sterilizers. So I had a job interview with them in 2011.

I was hoping to continue with my university's research of plasma sterilization at SARAYA, but for some reason, I ended up developing Rapid Freezer, our equipment that rapidly freezes food in chilled alcohol without causing any loss in its freshness and taste. SARAYA is a company that implements SDGs in many ways, and through the Rapid Freezer we are targeting SDG no.9, Industry, Innovation, and Infrastructure, developing the food cold chain not only in Japan but in many developing countries, creating business opportunities. Thanks to this project, I have seen parts of the world that I would have never visited by myself, meeting interesting people, including local celebrities while traveling to countries like Uganda, Kenya, Cambodia, Vietnam, and Malaysia to install our Rapid Freezers.

As you know, things do not always go as planned, but I think that’s what makes life more interesting. I appreciate the experiences that the company provided me, opening new doors for me.

Tell us about your background growing up in the south of Japan

|

| Kihara during Primary School. |

I was born into an average Japanese family that loved sports in one of the islands of Amakusa, Kumamoto Prefecture. Amakusa, which means "Heaven's Grass," is a series of islands off the west coast of Kyushu, the southernmost of the four main islands of Japan. Those islands are nature-rich and the people there are nice and laid back.

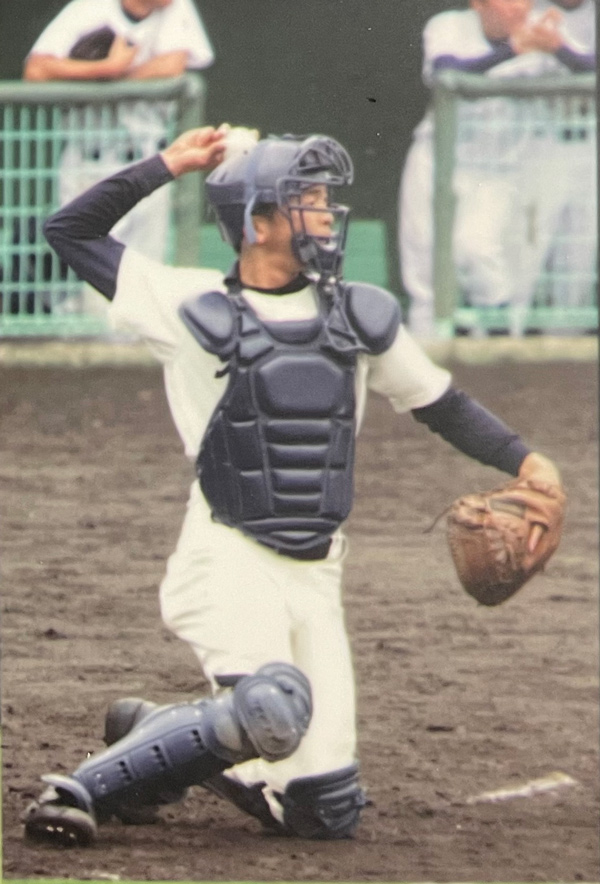

I was a very active and somewhat bossy child who sometimes misbehaved and annoyed my parents. I played baseball and belonged to the school baseball teams throughout elementary, junior high, and high school, winning many local tournaments. I was a rather well-known catcher there if I am allowed to say so myself. I dreamed of becoming a professional baseball player until when I was a junior high school student.

|

|

| As a catcher during high school. | Okinawa beach. |

I was fortunate to live in places like Kumamoto and Okinawa for my studies. There, nature was rich and people were laid-back. Maybe that's why I became the free-spirited, optimistic person I am today. I also love Osaka, the big city where I currently work and live. Happily, I love all the places where I have lived.

Could you tell us about your studies in Plasma Sterilization?

I got my first job at SARAYA after graduating in engineering, where I researched plasma sterilization. Plasma sterilization consists of high-energy electrons in plasma colliding with atoms and molecules to create highly reactive radicals that react chemically with bacteria, essentially killing them. The advantage is that it’s a dry, non-thermal sterilization process that it’s environmentally friendly by not producing any harmful by-products. It’s a new sterilization system, often used to sterilize medical devices that cannot be heated.

I thought it was fascinating that lights could kill germs. My professor was a passionate person and let us do many experiments in so many ways, learning a lot from him. Unfortunately, my current job has nothing to do with plasma sterilization, but the investigation methods I learned there, like how to create projects and follow through with challenging problems, have been quite useful in what I do at SARAYA.

By the way, SARAYA does apply a plasma sterilization system in one of our medical sterilizing machines called “Steriace”, which sterilizes medical equipment with a hydrogen peroxide solution containing peracetic acid, enabling efficient treatment of sterilant components at low temperature after sterilization.

What is your role at SARAYA?

My job is to develop a rapid freezer and continuously improve it.

When I first joined the company, I was assigned to the Medical Unit and was involved in developing medical equipment, but in my third year, I was transferred to the Instrument Design Unit where they developed the Rapid Freezer. Boy, it has been several challenging years!

It was a totally new field not only for me but also for the company. The hardest part was that there was nobody I could ask for guidance, no one having any experience nor knowledge about this technology. I was lost and didn’t even know where to begin. But I thought, ‘Let's just try it for now!’ with my Amakusa spirit and I moved on. To tell you the truth, it wasn’t easy at all, but nothing comes out unless you do something! So I did my best to make the machine better in whatever I came to think of. Fortunately, we were joined by a technical advisor later, and the level of product development of the Rapid Freezer finally took a step forward, as we came to research it in a more theoretical manner.

The system of freezing food rapidly in alcohol itself is not new, but with a trial-and-error process, we were able to make our original model. Most of all, as a manufacturer of alcohol solutions like hand sanitizer, we have developed our own alcohol solution to freeze more efficiently. When I look back, we have come a long way, all thanks to our team members and advisors.

What is Rapid Freezer?

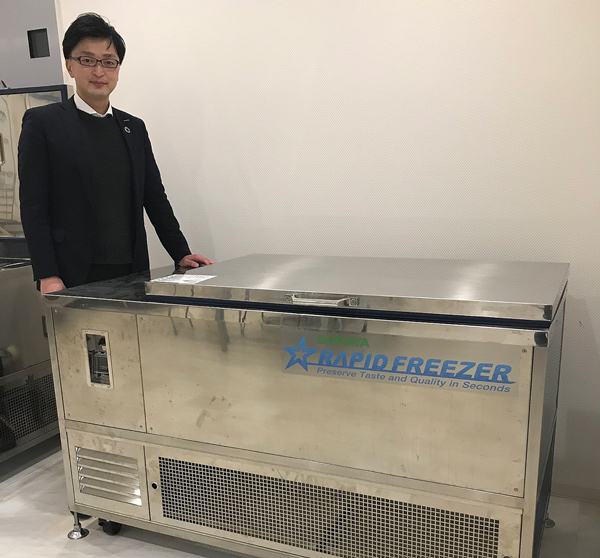

|

| Kihara posing with SARAYA’s Rapid Freezer. |

The Rapid Freezer is a machine used to rapidly freeze objects like food with an alcohol solution. Its freezing method consists of vacuuming pack food in a plastic bag and dip them in cold alcohol chilled to -30°C (-22°F). In that condition, food freezes within a few minutes while keeping the flavor and texture closer to what it normally is.

Foods tend to have water in them that crystallize when frozen. With food beginning to freeze at -1°C and almost reaching complete freeze at -5°C, the longer it passes through the maximum ice crystal formation zone (the temperature range at which ice crystals form), the larger the ice crystals become, and the more parts of the food are destroyed. To avoid this, instead of using a normal ice freezer, freezing with liquids will produce smaller ice crystals, since they freeze 20 times faster than gases. Rapid Freezer has a fast freezing speed, passing through the maximum ice crystal formation zone quickly and ensuring that ice crystals formed within the food are so small that they don’t end destroying cells, keeping any food fresh and tasty after it is thawed.

Thus, Rapid Freezer improves the quality of frozen foods. It reduces costs by bringing seasonal produce to the table all over the world all year round, prolonging their peak serving time, reducing food losses while cutting costs, since you can stock large quantities of food at their lowest price. For the food preparation industry, including restaurants, it can save manpower as you can prepare food way in advance without losing any quality, helping the time management of chefs.

Over the years, with my involvement as a development engineer, we have made several changes improving the original design, installing better filters, and simplifying its inner unit shape for easier cleaning. We also made sure to improve its isolation to prevent condensation, which can lead to hygiene problems.

On the liquid side, we also developed our own alcohol solution which makes food freezing more effective than other solutions. SARAYA is known for manufacturing hygiene solutions like alcohol hand sanitizers for decades, and with their know-how accumulated over decades, we have found an effective solution. Of course, as it is SARAYA’s nature, we will still keep working towards the improvement of our products.

Currently, we have 3 models which can freeze 5kg/hr, 10kg/hr, and 20kg/hr respectively. As Rapid Freezer gains popularity, we are now planning to make even larger machines for food processing factories, restaurant central kitchens, etc.

The project has been going on for 5 years and we are building up achievements thanks to our team members and advisors, as well as our distributors and customers.

SDG no. 9 aims to promote sustainable industrialization and infrastructure. What role does SARAYA’s rapid freezer play in achieving this?

I believe that building a solid cold chain is the key to the future, contributing to establishing sustainable industry and infrastructure around the world, and for that developing countries also need to be taken into account when developing technology. For example, since in certain countries replacement parts are not easily available, we have created modified versions of the Rapid Freezer to ease maintenance. While in Japan the cooling motor is installed inside the machine, our export models have it outside the main body, as a separate “air conditioner” unit that makes replacement easier in case of malfunction.

As I said before, only a few people within SARAYA had experience with Rapid Freezer and its field. When it came to overseas projects, it was even less. We had to check the operating environment, parts selection, laws and regulations, and so on. Having to communicate in different languages didn’t make it easier.

|

| A Rapid Freezer being unpackaged in Kenya. |

In recent times, since frozen foods go through a complete process of freezing, transportation, storage, and thawing before they are consumed, we are focused on improving the full food journey, not just the freezing part, to improving the quality of food in general. We are working on organizing information on how to properly treat food in all its stages so that people know how to correctly use Rapid Freezer effectively.

What is the plan in SARAYA regarding SDG9: Industry, Innovation, and Infrastructure?

Rapid Freezer, together with Shut-Man, our food vacuum packaging machine, are products that can help you reduce food loss and labor shortage, preserving the freshness and quality of food while improving your hygiene and sanitation control (HACCP). Through the use of these products, I am convinced we can improve the food industry by working towards SDG No. 9, “Industry, Innovation, and Infrastructure”, developing a food system solution (FSS) centered on the Rapid Freezer, in Japan and the rest of the world.

|

|

| Rapid Freezer, SARAYA’s rapid freezing machine. | Shut-Man, SARAYA’s food vacuum packaging machine. |

We are also advocating a new cook-chill and cook-freeze system using our Rapid Freezer to offer new and beneficial meal production processes. Cook-chill is rapid cooling of cooked food to reduce the core temperature to 3°C or lower within 90 minutes while cook-freeze is to freeze cooked food to reduce the core temperature of the food to -18°C or lower within 120 minutes, both for refrigerated storing.

To further enhance our solutions in hardware, software, and services, we have opened an experimental kitchen laboratory to experiment with the use of the Rapid Freezer in Osaka Municipal Wholesale East Market last August. There, we seek to develop a more efficient and effective way to use this fast freezing method.

Could you give us some words for the next generation?

I am not that old, so I don't have much life experience myself, but what I can say is that I appreciate the experiences at SARAYA so far. You do have “encounters” in your life. Encounters are sometimes “people” and sometimes “things”. I believe that encounters make your life interesting.

By encountering SARAYA and Rapid Freezer, my doors were opened and I was able to visit countries, meeting many interesting people that I would never meet. With those encounters, I continuously learned new things and adjusted myself. Encounters in my life gave me themes to explore.

Mr. Saraya, the company president, always encouraged me to have fun when working. I think having fun is what keeps you going. Sometimes you make mistakes and fail, but there is always room for corrections and improvements. Sometimes you can even start over. So don’t be afraid to take challenges.